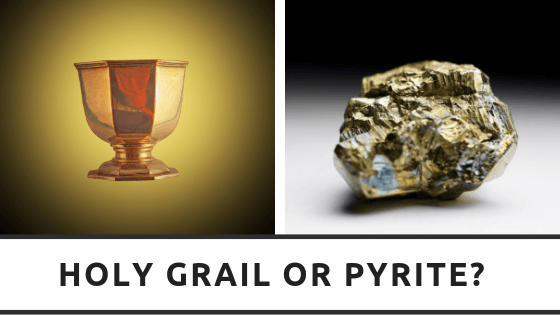

(a useful procurement strategy?)

We have had interesting engagements with 2 sophisticated OEM buyer organizations lately. Both these OEMs are equipment manufacturers seeking better supplier features—highly desirable potential customers for us!

Proficient Sourcing has a network of outstanding shops covering a many capabilities. Often we are successful in providing a valued supplier candidate who answers the need of the OEM. We are particularly interested in OEM’s seeking suppliers for equipment/machinery building. We have several suppliers specializing in this specific market, as elaborated by this link. We were optimistic about these opportunities.

However, we were not successful in these 2 cases (so far). These events provide an excellent opportunity to explore procurement strategy and how that may or may not work with specific suppliers.

We eventually learned both these OEMs have a long standing supplier base, and the OEM’s are reasonably happy with these suppliers. The parts they showed us are complex and fairly expensive, and were ingredients of “standard” equipment models. In other words, the RFQ was for existing device parts, not anything new or developmental. While relatively low volume work, it fits into our term “production” work.

A successful supplier over time means the acquisition of procedural knowledge and experience, not to mention a reasonable learning curve. Presumably there has been considerable interaction between buyer and supplier for the purpose of improving costs and leadtimes, as well as quality. Equipment purchases and/or modifications for the specific application may also be involved.

In both cases the OEM was “fishing” for a better deal—perhaps a 10-20% cost savings compared to their existing suppliers. Our quotes were close in a few cases, and not so close in others.

In analyzing why this was so, our suppliers noted they were competing against established suppliers. These suppliers have had the benefit of time to develop specific methods and equipment to maximize their relationships with these OEM’s. Absent some problem there was no compelling reason to change suppliers.

While pricing is always top of mind, in cases such as these, there is little chance of success. A new supplier in all but the most unusual circumstances cannot compete on an apples to apples basis with a good existing supplier, especially when the work is reasonably complex and difficult—which was the case in both the situations we faced.

It seems to us that a procurement strategy that employs supplier searches similar to the 2 we faced is going to be an expenditure of time with little likelihood of success. Since the existing suppliers are viewed as positive, what’s the point in seeking to change? And this in a time when manufacturers are busier and generally less interested in taking on new prospects.

We at Proficient Sourcing welcome the opportunity to bid on projects where an OEM seeks a new supplier for any number of reasons. But if the objective is to see if we can beat good and satisfactory suppliers, then please let us know before hand.

We would be very interested in your opinions about this, and really encourage contributions in our blog.