From time to time we’ve encountered companies that require machining or grinding of very large parts or assemblies. We found a shop that specializes in this very work with some of the largest and most accurate equipment under one roof in the country.

From time to time we’ve encountered companies that require machining or grinding of very large parts or assemblies. We found a shop that specializes in this very work with some of the largest and most accurate equipment under one roof in the country.

If you need machining on something larger than a 40” cube, we have a shop for you. This company has a workcenter that can handle pieces up to 88 FEET long, 14 feet wide, and 10 feet high in a climate-controlled plant with crane capacity up to 150,000 pounds.

Need large boring capability? If your requirements are less than 50 feet X, 14 feet Y, and 4 feet Z, it will fit with their largest of several CNC horizontal boring mills.

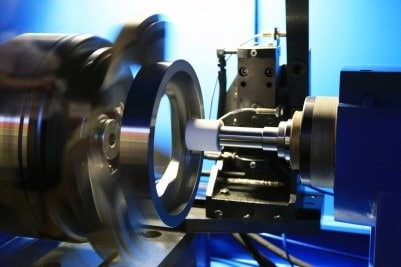

Perhaps surface grinding is on your list. This supplier has 3 very large and accurate double housing surface grinders. All have conventional and compound swivel heads, and the largest has 123” x 315” capacity.

There are several very large milling machines, which include vertical and right-angle heads to minimize costly setups, with fixed and adjustable rail types, and up to 5-axis, all with CNC controls.

Finally, there are several very accurate and versatile planers capable of achieving surfaces within 0.002”.

We stand ready to help with your very large projects. Just give us a call.