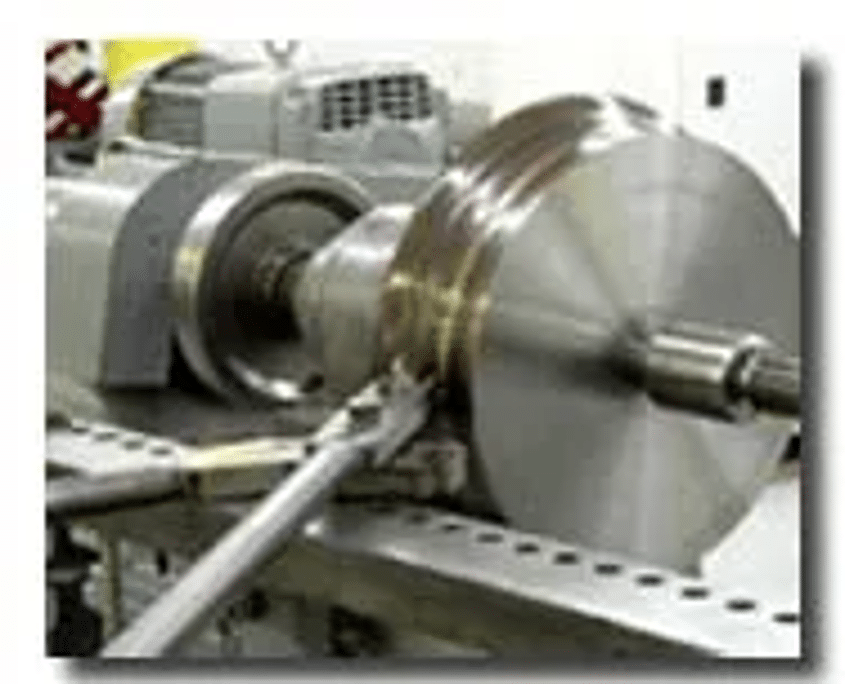

Metal Spinning is a forming process used to produce round hollow metal parts or shells. To produce a part, a sheet metal disc, or blank is spun on a lathe, while held against a spinning chuck, or mandrel, with a tailblock. As the disc rotates, spinning tools or rollers are used to push the metal down to the spinning chuck or mandrel. The material thickness of the finished part can be closely controlled, with reduction of 10% to 50%. Metal spinning is a low fixed cost, high variable cost process. Tooling and setup is relatively inexpensive, while production time will run from 5 to 15 minutes.

Metal spinning is the most cost-effective way to produce prototypes, small quantity orders and for materials that are highly pliable such as O-tempered aluminum and lighter gage steel and stainless steel.

Here are some common uses of metal spinning:

- Cookware and Kitchen Equipment: Items such as pots, pans, bowls, and stainless steel utensils are often made using metal spinning because it allows for the creation of smooth, circular items with uniform thickness.

- Automotive Components: Parts like air cleaner assemblies, wheel rims, and certain engine parts (such as pulleys) can be manufactured using metal spinning, benefiting from the process's ability to produce strong, lightweight components.

- Aerospace and Aviation Parts: Components for aircraft and spacecraft, including nose cones, fuel tanks, and various ducting components, are made through metal spinning. The process is valued for its precision and the ability to work with high-strength, lightweight materials like aluminum and titanium.

- Architectural and Decorative Items: Metal spinning is used to create decorative elements such as lamp bases, candlesticks, and architectural details that require a symmetrical, circular form.

- Industrial Applications: It is also used in making parts for machinery, including fan blades, gas cylinders, and venturi tubes, as well as for various tanks and vessels that require a circular shape.

- Musical Instruments: Certain components of musical instruments, particularly brass and woodwind, can be produced through metal spinning. This includes parts like trumpet bells and French horn bells.

- Lighting Equipment: Reflector cones for lamps and other lighting fixtures are commonly produced using metal spinning, allowing for precise control over the shape and the directionality of light.

Our metal spinning company can spin metal up to 104″ in diameter with thicknesses ranging from .010″ to .187″ and with tolerances as close as .002″. They use utilize a combination of traditional hand spinning equipment, state of the art CNC spinning equipment, and the latest in flat plane and 3D laser cutting machinery.

The metal spinning process is particularly advantageous for low or medium volume production runs for concentric symmetric parts, especially when the cost of metal stamping dies is prohibitive. It is also used to create tank heads for pressure vessels, storage tanks, and other process equipment

Advantages of metal spinning include simple setup and quick changeover, which lead to short lead times for new parts. It also allows for design changes with minimum expense. The process improves the tensile strength within the finished material and provides dimensional stability with precise tolerances. Furthermore, it refines and strengthens the grain structure, leading to high integrity and reliability for structural parts

Because spun parts have no seams, they can withstand higher internal or external pressures, which is beneficial for products that require structural integrity.

Tooling is custom made per your specifications. From blueprint to finished product, no shape is too simple nor too complex. The staff offers specialized consulting on materials and finishing. The highly specialized production facility and over 40 years of experience allow our metal spinning company to fabricate complex metal shapes at a significant cost advantage over other methods.