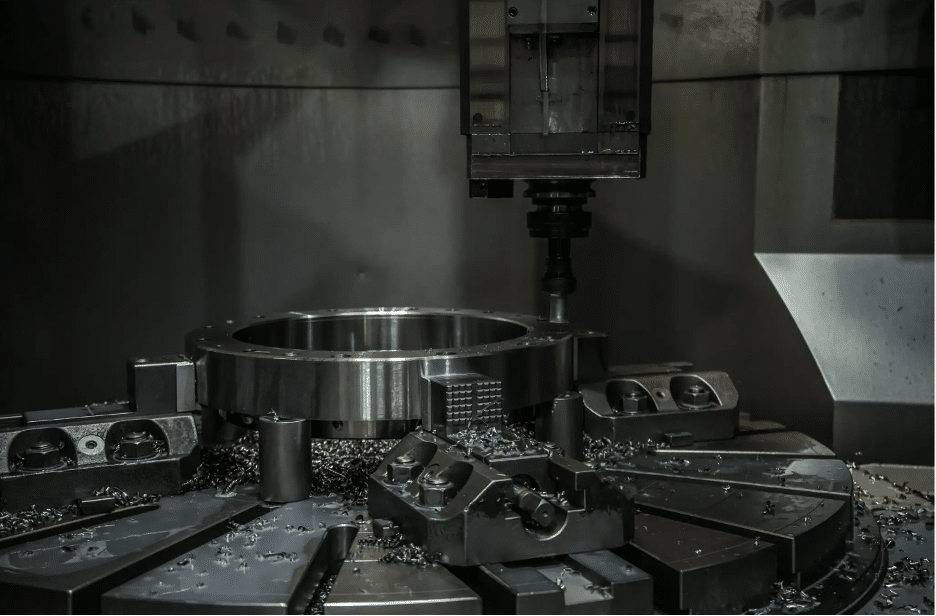

OEM custom manufacturing needs for machined parts has been our most frequent supplier search. To service that potential clientele, we have a dozen machining shops scattered throughout the eastern US. Each has a long history of happy customers and on-time delivery of goods built to spec with competitive pricing. They feature the ability to customize orders and adapt to unique client needs, including handling a variety of materials and specifications.

High precision milling and turning! ISO and AS certified, ITAR registered, DAV and woman owned and even Hub Zone locations are all available. Whether large or small parts, high volumes or complicated one-off’s, even prototypes, excellent candidates are just a call away so you save time and effort without cost!

Milling and turning equipment choices include:

- Multiple medium-to-large machining centers-up to 60” cubes

- Large part boring mills—full contouring 4th axis, 44,000 pound weight capacity

- 5 axis machining centers - up to 32” cube

- Vertical Turret Lathes—up to 93” diameter swing x 36” height 18,000 pound capacity

- Large part horizontal lathe—up to 60” diameter and 384” length

• Large part horizontal lathe—up to 60” diameter and 384” length

These shops also have extensive supportive capabilities, including grinding, honing, edm, fabrication, painting, stamping, manual and robotic welding, and assembly. In many cases, we can source so requirements are met under a single roof, and usually offer multiple candidates.

Our network is experienced in many areas where customer needs have been successfully met. For example:

- Custom equipment components: machining and fabrication

- Motor and pump housings

- Valve bodies

- Volutes and turbines

- Gearboxes

- Hose form Tooling, cavities, nests, molds, gages, and check fixtures

- Canning press components

- Machine bases, frames, and platens

- Swager spare parts and rebuilds

- Guides, Rails, Cylinders, Flanges, Bonnets, and Rocker Arms

- Crossheads, Yokes, Wedges

- Machinery building (and refurbishing)

- Large shaft turning

- Heavy weldments

- Structural components

- Reverse engineering of components

- Elevator Machine blocking assemblies, couplings, adapter plates and tubes

- Convex and concave seismic plates

What this simply means is these suppliers can do almost any size or type of part in quantity. Their quality systems provide reliable and precise consistency with superb quality. You can be confident that your sophisticated part requirements will be professionally managed.

All this available quickly. Just text or call 513-489-5252.