OEM’s in many industries are continuously seeking higher performing materials for their products. This is especially true for companies involved in aircraft and automotive, perhaps even for other vehicle types. And, of course, there are numerous military applications for higher strength, lighter weight, impact toughness, corrosion resistance, low flame, smoke, and toxicity, and RF transparency. Also, the reinforcing fiber type can be either electrically conductive or an insulator.

OEM’s in many industries are continuously seeking higher performing materials for their products. This is especially true for companies involved in aircraft and automotive, perhaps even for other vehicle types. And, of course, there are numerous military applications for higher strength, lighter weight, impact toughness, corrosion resistance, low flame, smoke, and toxicity, and RF transparency. Also, the reinforcing fiber type can be either electrically conductive or an insulator.

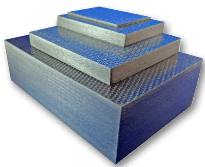

As you can see, both the thermoplastic selection as well as the fiber type (carbon, E-glass, or S-glass) gives you a vast spectrum of performance characteristics.

Just one example tells a very good story. If carbon fiber reinforced thermoplastics are appropriate for your application, you might expect equivalent strength to steel with 20% of the weight. If compared to aluminum, the weight would be 2/3 that of the aluminum for equivalent strength.

When your applications need these characteristics, we have a supplier that might be just the answer from concept through full scale production.

First, we can assist you in selecting a thermoplastic compound that gives you the material properties you need.

Second, we can assist in selecting the fiber or fiber combination that can provide the performance enhancements required—perhaps even exceeding your design targets. Continuous fiber reinforcement maximizes the performance of the materials, and can be combined with long fibers in specific component areas for ribs and bosses. Combinations of fiber types can be used to take advantage of material properties and to optimize part performance as well as meeting cost objectives.

Third, manufacturing processes with necessary tooling will be employed to produce your components. If prototypes or

experimental initial samples are part of the plan, lower cost molds can be used. Then, when higher volumes are needed, appropriately longer lived tooling can be added to the project.

Continuous Fiber Reinforced Thermoplastic parts are employed in a variety of industries with demanding material requirements such as aerospace. The superior corrosion resistance and impact resistance of our molded parts make them useful for oil and gas applications. Light weight, high strength and high impact toughness are particularly applicable to sporting goods and numerous military applications.

Thus, if you require superior material performance with strength to weight considerations we may have just the answer.