We feature several shops with large gantry or bridge mills for your very large milling requirements. Here’s just a sample of some of these milling equipment options when you need LARGE:

- Fixed rail type: With a capacity of 98 feet x 17.5 feet x 12 feet, this machine features a 60-inch Z-axis ram travel and assorted spindle units, including a 2-axis nutating head and ACC.

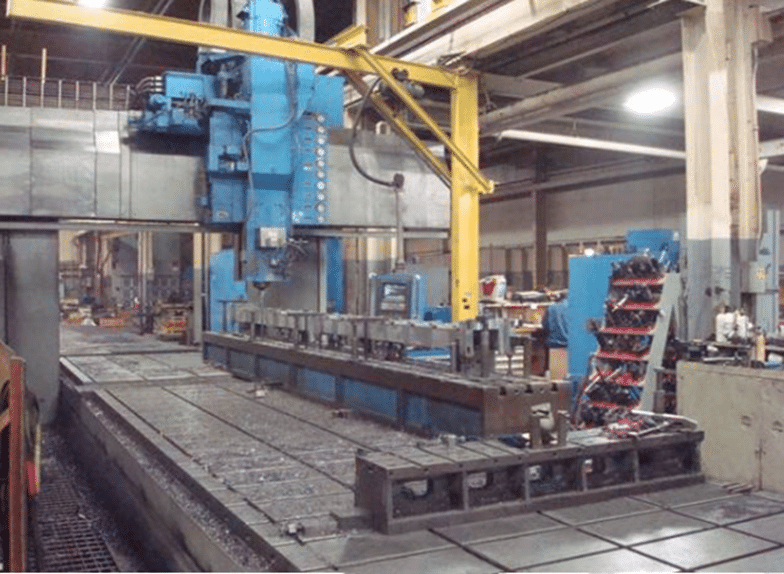

- Fixed rail type: With a capacity of 98 inches x 63 inches x 539 inches, this machine (shown below) has an 88-foot x 539-inch T-slotted work table and 39 inches of Z-axis ram travel. It also features three right-angle heads and a chip conveyor.

- Adjustable rail type: With a capacity of 114 inches x 112 inches x 372 inches, this machine has 39 inches of Z-axis ram travel and two 98-inch x 157-inch T-slotted tables with automatic coupling. They also feature assorted spindle units, including a 2-axis nutating head and ACC.

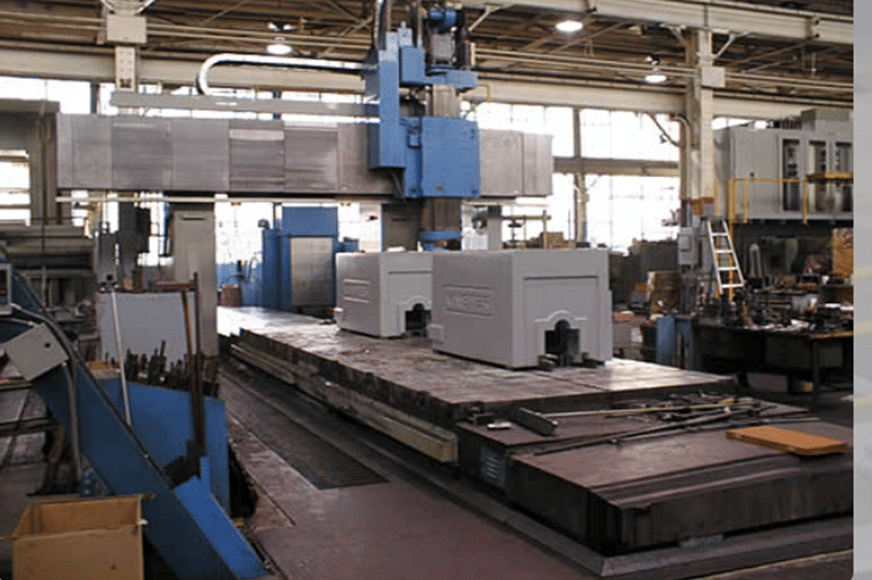

- Fixed rail type: With a capacity of 108 inches x 80 inches x 315 inches, this machine (shown below) has 39 inches of Z-axis ram travel and a 98-inch x 315-inch T-slotted table. It also features assorted spindle units, including a 2-axis nutating head and ACC.

- Double column machining center with 206”X, 118”Y and 43.3”Z travel. 360 degree right angle head with 1 degree increments.

- Vertical bridge mill; 472”X, 11-“Y, and 40”Z.

As you can see, there are several very large machines (there are more than those shown) available to solve your requirement for LARGE.

Our large gantry and bridge milling machines offer unparalleled precision, efficiency, and the ability to handle large workpieces. With a wide range of machines available in almost limitless configurations, you are sure to find the ideal solution for your very large machining needs. In conclusion, large gantry or bridge milling machines are the ultimate solution for industries and organizations that require precise, very large machining of materials.

Click here if you also need large fabrications!

Typical customers for this large milling include:

Aerospace Industry: Large gantry milling machines are used to manufacture large components like wing spars, fuselage sections, and other structural parts.

Shipbuilding and Marine Industry: These machines are essential for machining large parts of ships, such as hull sections, deck parts, and other structural elements.

Automotive Industry: Large gantry milling machines are particularly useful for producing large molds and dies used in the manufacturing of automotive parts.

Heavy Machinery Manufacturers: Companies that produce large-scale industrial machinery or equipment, like turbines, generators, and large engines, rely on these machines.

Energy Sector: Large gantry milling machines are used in the production of large components for wind turbines, hydroelectric power plants, and components for nuclear reactors.

Rail Industry: These machines are vital for the production of large parts of locomotives and railroad cars, as well as the maintenance and refurbishing of these parts.

Construction Equipment Manufacturers: Large gantry milling machines are used to create components of heavy construction machinery like cranes, bulldozers, and excavators.

Tool and Die Makers: These machines are essential for producing large molds, dies, and other precision tools used in various manufacturing processes.

Research and Development Facilities: Large gantry milling machines are used for prototyping and developing large-scale industrial components.

Defense and Military: These machines are crucial for manufacturing and repairing large-scale military equipment and vehicles.

Completion of your large parts might also require precise grinding, and we offer very large facilities for this as well. For those requiring the ultimate in surface finishing, our surface grinders stand ready, capable of achieving tolerances within tenths, equipped for various grinding techniques including concave, convex, and shuttle crossrail grinding.

This photo is a 123” x 315” capacity double housing grinder with conventional and compound swivel heads.

Our shop with the largest part milling and grinding capability has overhead crane capacity of 150,000 pounds.

Finally, Do you need ultra-high precision boring milling? One supplier candidate has 2 room with 8 ultra-high precision SIP boring mills! Here is just one: 60”X, 48”Y, and 26”Z and a B axis rotating table:

These shops specializing in very large milling have a wide variety of welding and other fabrication options available, and in 2 cases a building full of other machining and turning options.

If you need LARGE, we’re ready whenever you are! Just give us a call at (513) 489-5252 to get things started.