Our network of companies specializes in the manufacturing of a wide range of wire products, catering to diverse industry needs. From retail-specific point of purchase (POP) racks, baskets, shelving and sign holders to more substantial items for automotive, our several wire formers are ready to meet your needs.

In addition to wire products, our ISO and ITAR spring source specializes in the design and production of high-quality extension and compression springs for industries where precision manufacturing techniques are essential. The company prides itself on its rapid turnaround and cost-effective manufacturing of both simple and complex spring shapes, making it an ideal partner for businesses in need of reliable spring solutions.

Wire products available cover a wide and diverse spectrum of available solutions for you. Needless to say, manufacturing equipment includes tube lasers, press brakes, laser cutting, fourslides, vertical forming, CNC wire formers, various welding types and powder coating.

A few product examples include:

Material handling carts:

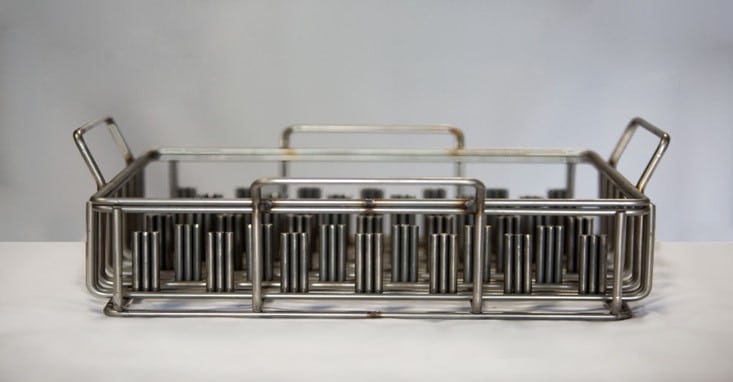

All manner of wire baskets:

Guarding for equipment and fans:

Even architectural items and furniture:

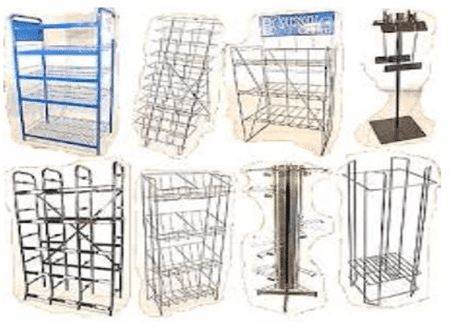

POP displays:

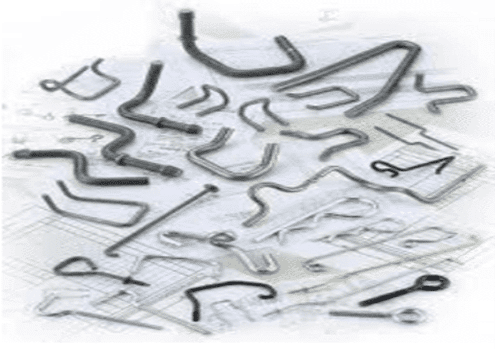

Our TS certified supplier specializes in heavier wire applications—automotive seat strikers and exhaust hangers, for example:

Specialties are many. Pivoting rug displays for one, and this series of medical parts is another:

- Basket to Hold Medical Accessories

- Laptop Stand

- Medical Monitor Stand

- Bracket to fasten laptop stand securely

- Bracket to fasten monitor stand

- Heavy Duty Rolling Base Plate

- Hand Sanitizer Stand

- Hand Sanitizer Dispensers

- Water Bag Holder – IV Bag Holder

- Basket to hold notebooks and files

- Bracket to fasten baskets securely

- Basket to hold blood pressure and other equipment

Springs are similar to wire forms but serve different purposes. Springs are devices designed to store mechanical energy for use in applications that require compressive, tensile, or torsion force. While they are often thought of in their cylindrical coiled form, they come in numerous other shapes, such as barrel (wider in the middle than at both ends), conical (wide at one end and narrow at the other), and hourglass (narrower in the middle than at both ends). Variable pitch designs—springs with variable wire thickness—are also available.

Our ISO certified and ITAR springs supplier delivers durable, high quality custom springs to many varied industries, including:

- Aerospace

- Electronics

- Lawn and Garden

- Communications

- Military

- Medical

- Oil and Gas

Some of the most popular spring styles are:

- Belleville springs: disc-shaped springs—also known as coned disc springs and conical spring washers—designed to apply tension and flatten under a set load

- Compression springs: springs designed to shorten as load is applied

- Extension springs: springs—also referred to as tension springs—designed to stretch as load is applied

- Torsion and double torsion springs: springs designs to twist when load is applied

In addition to these standard designs, specialty and custom springs can be manufactured for more demanding applications. Our capabilities include:

- Wire size: .004 to .472 inches

- Helix direction: left and right

- In-house finishing: powder coating, color coding, ground square, shot peening, stress relieving, and tumbling

If it’s made of wire, we have excellent and experienced candidates to address your needs. Call us at (513) 489-5252 to get the solutions started!